Atlanta High-Torque (HT) Servo Reducers

This standard range of Servo Reducers are perfect for use in applications that demand high performance, precise positioning and repeatability. They were specifically developed for use with state-of-the-art servo motor technology, providing tight integration of the motor to the unit. Angular backlash of less than 1 arc-minutes is provided standard.

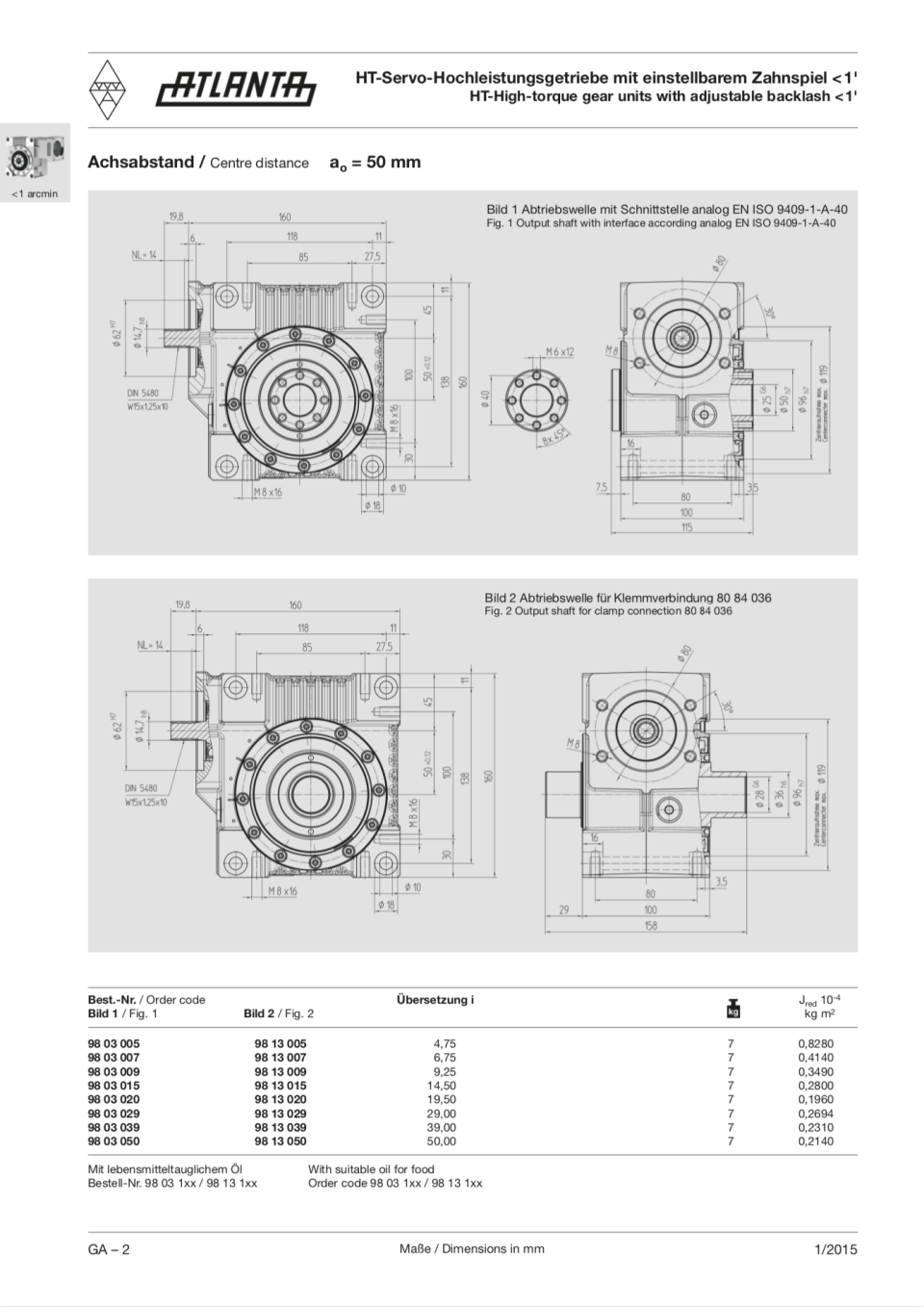

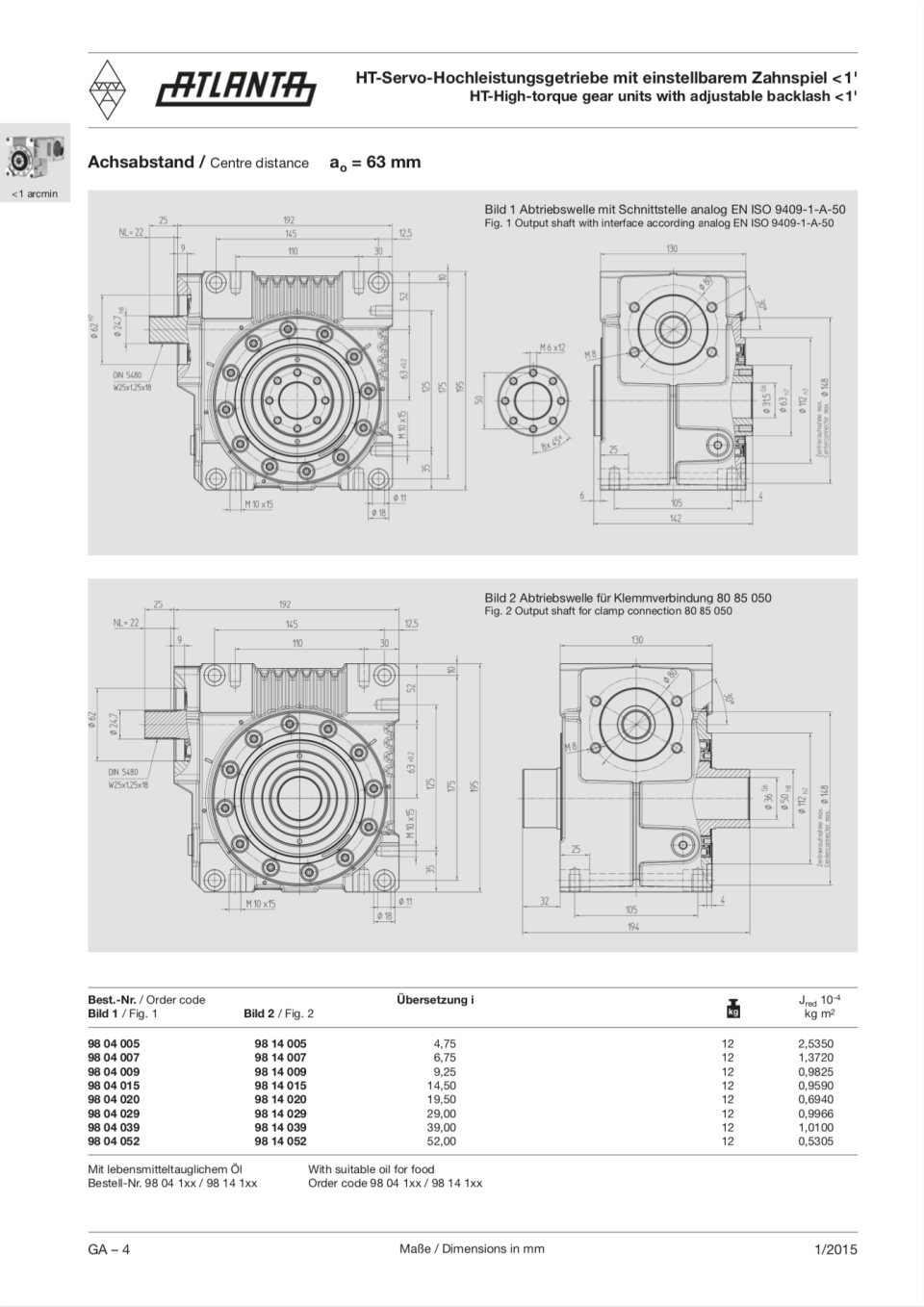

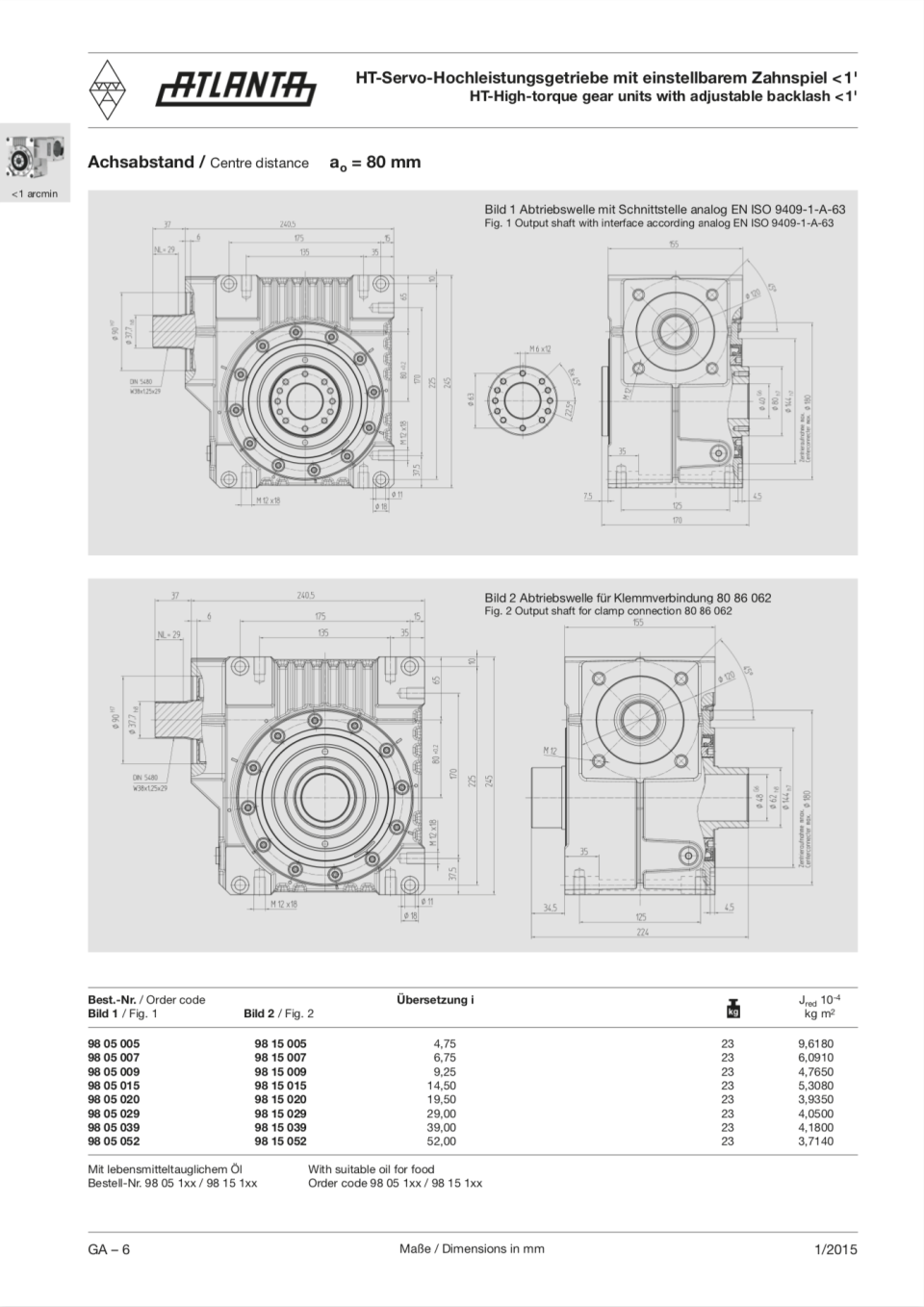

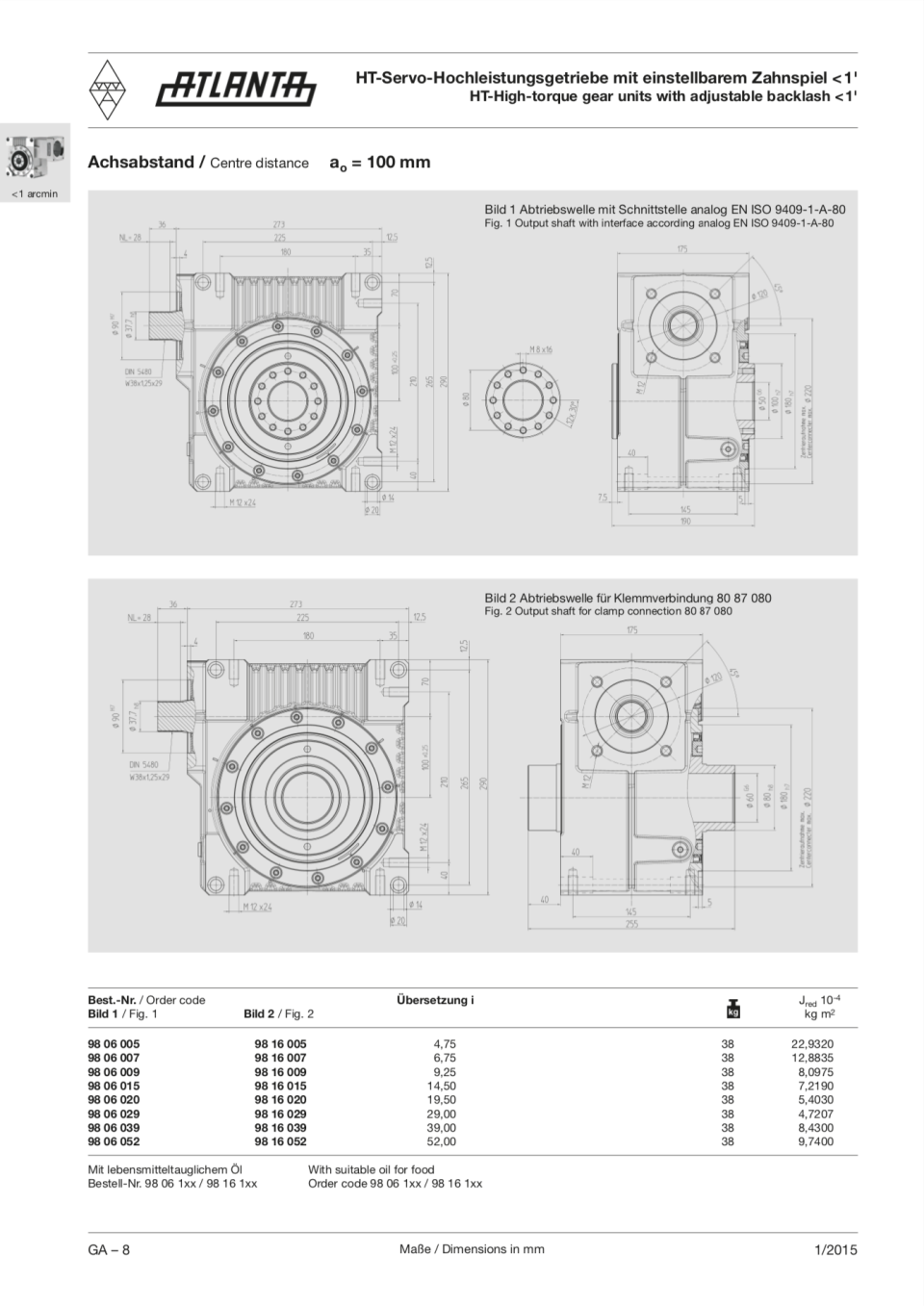

They are available in four sizes (50 mm to 100 mm center distance) with input speeds up to 5,000 rpm, reduction ratios from 4.75 to 52:1 and output torque capacities up to 1700Nm. A wide range of motor couplings and mounting flanges are available for assembly to virtually all servo motors, and the hollow bore output can be used to mount output shafts, pinion shafts, or other drive elements.

Typical applications for these reducers include precision rotary axis drives, traveling gantries & columns, material handling axis drives, zero-backlash axis drives and electronic line shafting. Industries served include Material Handling, Automation, Aerospace, Machine Tool and Robotics.

The following are typical features of our HT-Servo Gear Units: