- News

- Next generation Sinamics S210

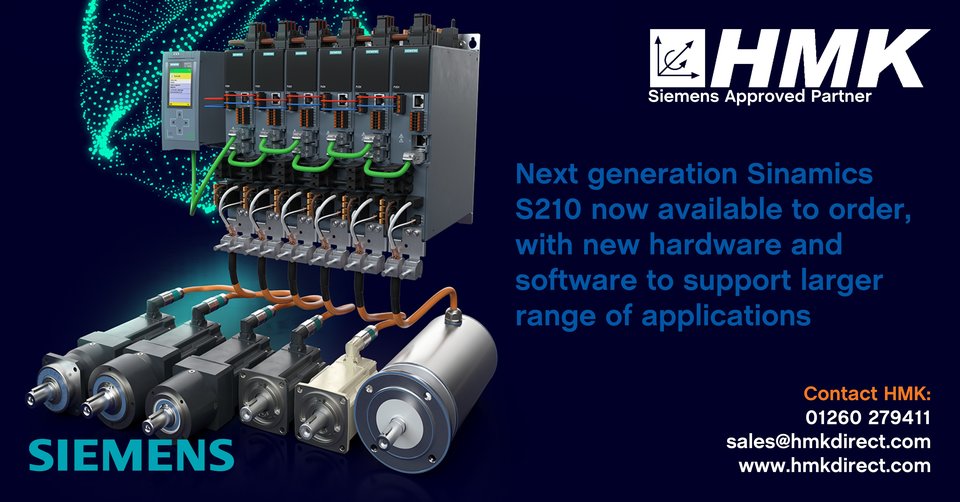

Next generation Sinamics S210 now supports larger range of applications

Siemens has launched the next generation Sinamics S210 servo drive system which now includes new hardware and software to support an even larger range of applications.

The latest innovations from our partner Siemens include:

- New V6 software generation with new functions like a single positioner to reduce the load of the controller, and EtherNet/IP to allow third-party controllers to be connected

- Simulation via DriveSim Advanced enables virtual commissioning in advance, ensuring drive process requirements are met efficiently and cost-effectively

- New hardware architecture with functional enhancements like a second encoder interface and 3C3 (H2S and SO2) coating increases precision and robustness

The servo drive system is especially suitable for applications with high dynamics in the power range between 50 W and 7 kW, for example, machines for packaging, pick and place applications, and digital printing.

For HMK customers, the key benefits of the new and improved S210, include:

Basic and Extended Safety Integrated functions - the new Sinamics S210 ensures the comprehensive implementation of the safety concept in the machine and meets the requirements of SIL3 (EN 61508) and PL e (EN ISO 13849-1). This means the safety performance of the drive is increased, so the electrical design of the machine can be simplified to achieve the same level of protection with less components, taking up less space and design time.

The EPOS single positioner is now available as a technology function for the Sinamics S210. With this function module, high-precision motion control positioning tasks can be implemented quickly and easily in the converter because positioning tasks can be calculated directly in the drive.

This means that for certain applications, the S210 is no longer just to be used with the higher end larger 1500PLC, it also allows it to be used on smaller machines with 1200PLC control, thereby offering the advantages of the S210 system -single cable power and feedback, reduced wiring, longer cable runs, SIL3 Safety and Profisafe, on smaller machines.

It also means that the size of the processor can be reduced as this method of control reduces the load on the controller depending on the application requirements.

Communication via EtherNet/IP: This means it could be used with Allen Bradley systems. Customers could standardise on drive system, no matter the controller platform, reducing the time taken to change the design of the machine.

As a long-standing Siemens partner for more than 30 years, HMK can supply our customers with the new Sinamics S210 servo drive system, alongside our engineering expertise.

Get in touch to discuss your application and how these new features could benefit you.

You can find out more about the Sinamics servo drive range, including the S210 here.